Jacuzzi Jets – Hydro Therapy Massage

Jacuzzi Jets are mostly manufactured from SABS Approved Polymers that fuse together very well with PVC Pipes once PVC weld or Tangit has been applied to both surfaces.

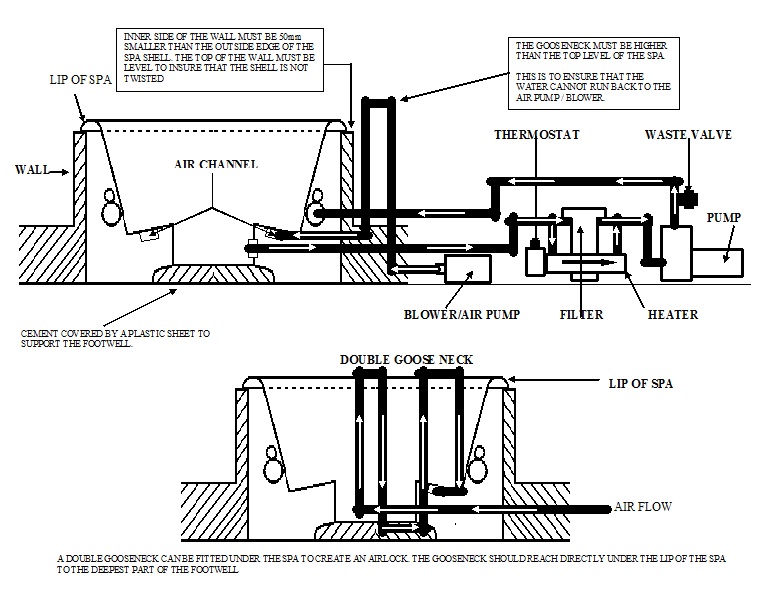

There are many variations of these jets on the market. The most common would be the 50 mm / 32 mm pipe combination. Meaning that the water channel runs in the 50 mm pipe and the Venturi Air System is connected to the 32 mm pipe.

This jet has a venturi system, which allows for air to be sucked in to the water channel to boost the Jacuzzi Jets Pressure.

The other type of popular Jacuzzi Jets are the 32 mm / 32 mm configuration. These type of Jacuzzi Jets are used in installations where there is not adequate enough space.

The Venturi system is attached to an Air Control (a type of dial situated on top of your Jacuzzi).