Jacuzzi Hot Tub Shells

Jacuzzi Hot Tub Shells are manufactured from high grade sanitary acrylic sheets supplied by Lucite International a UK based Company With branches all over the world.

There used to be a whole variety of colors to choose from in South Africa a few years ago, but with the economy slowly deteriorating, many of the Jacuzzi manufacturers have scaled down on their production as the demand has dropped significantly.

This resulted in Lucite international limiting their export colors to South Africa to only white and Kalahari Beige, which is a sand brown color, very beautiful and also the most popular sheet color. Unfortunately, sometimes there is only white available.

These Acrylic sheets are heated in an oven until about 141 degrees centigrade, before they are clamped to a mold. The air is sucked out from under the sheet and this causes the acrylic sheet to take on the form of the mold.

Once the sheet has cooled enough, it is removed from the mold and trimmed in order for it to be re-in forced with fiber glass.

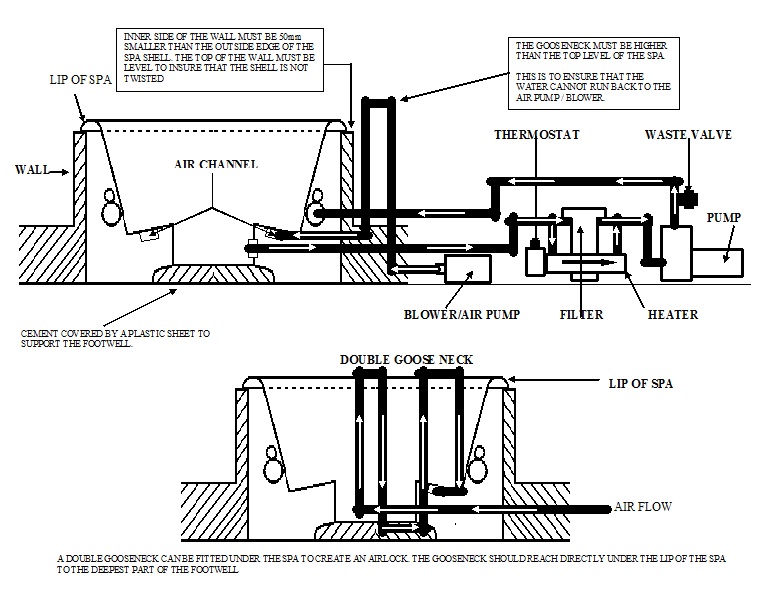

Once the Jacuzzi has been sprayed with Fiber Glass and dried for at least 2 Hours it can then be plumbed according to the Customers Specifications. Be careful not to drill too many holes in the bath, as this could weaken the Jacuzzi support structure.

Many funny and unwanted cracks and bulges will start appearing everywhere. It is very important to support the Foot Well of the Jacuzzi with either Cement or River Sand.